Wanted – skilled and enthusiastic chemist to work one year in New Zealand then another in Belgium – the ad for a postdoc that fired the imagination of more than 80 hopefuls around the world. The new position marks the beginning of a unique collaboration between New Zealand Crown research institute Scion and Belgium-based VITO (Vlaamse Instelling voor Technologisch Onderzoek) to accelerate the development of functional bio-aromatic chemicals from trees.

Scion’s manufacturing and bioproducts research focuses on supporting New Zealand’s manufacturers and brand owners with innovative technologies that utilise sustainably-derived, biobased resources. VITO is a leading European independent research and technology organisation in the areas of cleantech and sustainable development, elaborating solutions for the large societal challenges of today.

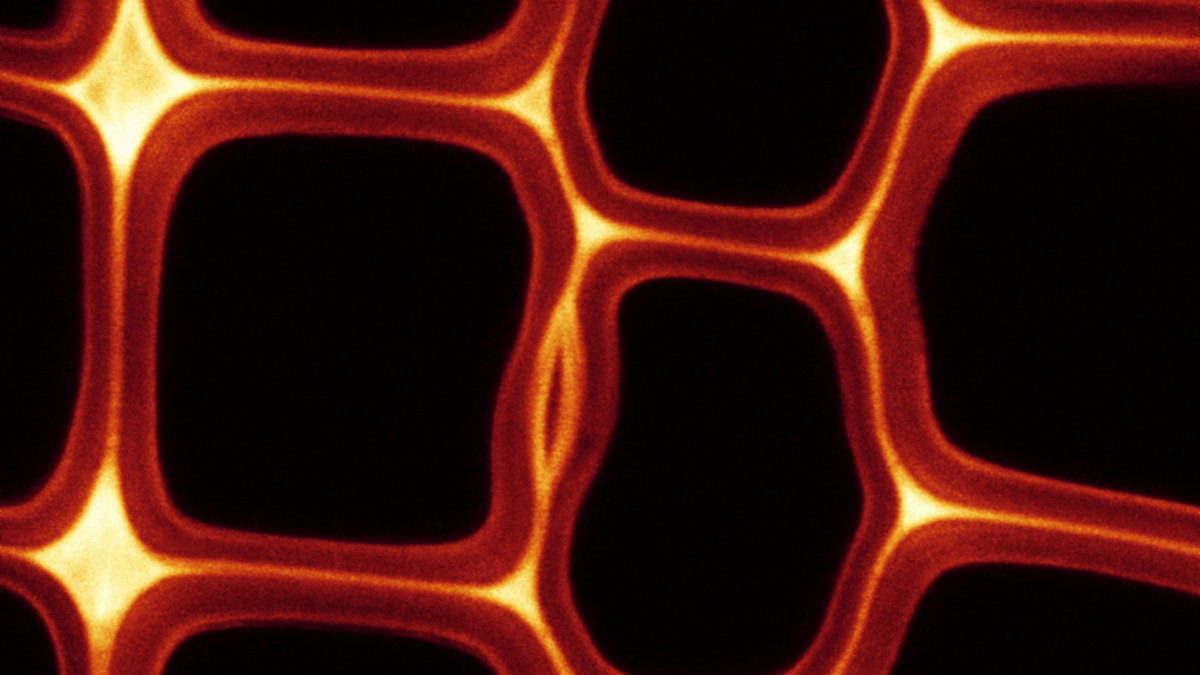

“We want to use the complementary strengths of both organisations,” says Dr Florian Graichen, who is Science Leader for Biopolymers and Chemicals at Scion and has also worked for VITO. “Scion brings experience in the chemistry of biomaterials and creating new bioproducts. VITO has expertise in fractionation and separation technology using ceramic or polymer membranes.

Both organisations see huge potential in utilising the interesting structure and functionality of lignin, the material that gives rigidity to cell walls in trees and plants and makes up to one quarter to one third of the dry weight of wood.

Lignin is abundant and cheap and a by-product of pulp and paper mills and lignocellulose biorefineries. “It is a complex polymer and a natural source of highly functional aromatic units,”says Dr Kirk Torr, who will lead the Scion side of the international project.

Lignin as a raw material presents three separate challenges. “The first is to split the strong lignin structure in the right places to retain the chemically interesting building blocks. The second is to separate the different components from the lignin ‘soup’. Lastly, there is the challenge of turning the new bioaromatic molecules into high value products,” says Kirk.

The materials and products will go beyond clean, green and renewable according to Dr Marjorie Dubreuil, Project Leader Bioaromatics at VITO. “Lignin has natural features we can build on, such as 3-dimensional structures and asymmetry. We want to design products that aren’t possible to manufacture from petrochemical resources; products that offer performance attributes beyond sustainability.”

The project, using bio-based chemistry and sustainable raw materials, is a good example of green chemistry. The philosophy of green chemistry seeks to reduce any negative impacts of chemistry on the environment by using fewer and/or sustainable natural resources and by preventing pollution at the source. In particular, it focusses on designing new processes and products that use renewable feedstocks, are energy efficient and minimise the use of, and generation of, hazardous substances.

Towards a New Zealand bio-based economy

Bioaromatic chemicals made from lignin could be an important piece of the puzzle necessary to make biorefining in New Zealand economically feasible.

A biorefinery is a facility that integrates biomass conversion processes and equipment to produce fuels, power, and value-added chemicals from biomass feedstocks. The biorefinery concept is analogous to today’s petroleum refinery, which produce multiple fuels and products from petroleum.

The co-production of high value products derived from lignin could be just the thing to push a biorefinery’s books into the black.

New Zealand’s forest industry, with trees, processing sites and supporting infrastructure already in place and near to one another, is poised to embrace bio-refining and create a bio-based economy with the potential to revitalise regions such as the central North Island and Bay of Plenty.

Looking towards the future, Florian says, “We need to be able to demonstrate that making bioaromatics from materials such as lignin is both possible and commercially viable. Even more importantly, we have to show we can use the bioaromatics to make bioproducts that people can see, feel, touch and desire. This is what will drive the development of bio-industries and a green and sustainable future for New Zealand and the rest of the world.”

For more information contact Florian Graichen.

Leave a comment