For a little creature the humble honeybee packs a very big punch. Both environmentally and economically. Not only do honeybees have a remarkable ability to willingly produce sweet liquid gold in the form of honey, they are also responsible for pollinating over one third of the world’s food producing crops. We need only to observe the myriad of enthusiastic apiculture professionals who (quite literally) swarmed to this year’s 2016 New Zealand Apiculture Conference in Rotorua, to realise just what a big deal the honeybee is.

In 2015 New Zealand’s thriving honey industry alone was valued at an estimated $242 million, $223 of that being our prized mānuka, renowned globally for its remarkable medicinal and health giving properties. By 2028 speaker Lou Gallagher, from New Zealand Ministry of Primary Industries (MPI), says NZ’s apiculture industry aims to reach a target of $1.2 billion in honey related exports. If the industry worked quickly towards reforesting more of New Zealand’s marginal land with mānuka scrub, this figure could probably be reached earlier given the burgeoning international demand for our native mānuka honey and related products.

Over and above their plentiful honey bounty, 5+ a day favourites and Kiwi export staples like apples, kiwifruit, pears are also vitally dependent on commercial honey bees for pollination. As are a raft of tasty fresh goodies such as stone fruit, berries, almonds, figs, sunflower seeds, onions and carrots. According to MPI, crop pollination in itself is worth a staggering $4.5 billion annually. And John Hartnell, Chair of Apiculture New Zealand, the peak industry body representing New Zealand Apiculture and Chair of the ApiNZ conference steering committee, says the industry is heading towards $500 million when honey related exports, domestic sales & direct pollination income is included. So it’s fair to say that the honeybee is a big deal – especially in New Zealand.

Themed “Bee Business – Science: Health: Trade”, the 2016 New Zealand Apiculture conference attracted over 1400 enthusiastic commercial and hobbyist bee keepers, honey producers and suppliers as well as scientists and research professionals from a raft of quasi government agencies from all over the world to network and learn about the latest and greatest happening in the apiculture industry. With an excess of 100 trade exhibitors, the conference also boasted the largest trade exhibition ever assembled for the industry. The extent to which you could feel the passion, knowledge and enthusiasm for our flying honey-producing friends was nothing short of remarkable.

However, despite New Zealand’s unique ability to produce the most valuable and medicinally blessed honey in the world (mānuka), the apiculture sector has been slow to innovate and is rife with traditionalism. It goes without saying that honeybee awareness and education is a crucial aspect of the apiculture industry’s survival. But from an economic perspective so too is the development of new and emerging innovations and technologies that have the ability to extract even more value from New Zealand’s liquid gold.

So I was interested in discovering whether any innovations and technologies were emerging in our apiculture sector to squeeze even more value from New Zealand’s honey and our bees. Fortunately, Apiculture 2016 unveiled a number of standout emerging innovations along the entire beekeeping and honey production value chain from bee nutrition, disease prevention and hive health to extraction and distribution. Those particularly worthy of mention are profiled below.

It all starts with a healthy honey bee

Thriving bee health and honey production all starts with gut health and sufficient protein level. So if you think protein supplements were for gym buffs of the human kind only, think again. The greater the protein levels in the hive, the healthier the honeybee. Healthy honeybees boost colony strength, population and brood productions resulting in a more effective pollination season and higher honey yields. A win-win-win for the industry. But with rising CO2 levels in the environment, protein levels in floral pollen have dramatically reduced, starving bees of nutrition – by as much as 18% according to the Royal Society B, biological research journal.

MegaBee, California based specialists in honeybee nutrition, has spent close to a decade researching and building the most optimal Ph balanced protein feed on the market to promote a healthy gut flora, reduce honeybee diseases and improve productivity. Served as a “protein patty” to the bees, founder, Dr Gordon Wardell says MegaBee contains all 10 essential amino acids in their proper ratios and is proven to increase the lifespan of the adult honeybee by 20%. MegaBee supplementation also triples brood production, produces higher honey yields and increases royal jelly production (a substance secreted by honeybee workers and fed to larvae being raised as potential queen bees) of hives – vital for keeping bee colonies in constant exponential growth – when compared with straight floral pollen and other protein alternatives like soy and sugar syrup. At a time where New Zealand’s mānuka is fetching record export prices and the horticulture industry is struggling to secure enough bees to pollinate its multibillion-dollar fruit and vegetable crops, grass roots innovations like MegaBee could be one of the honey holy grails that New Zealand beekeepers need to ensure the industry is producing enough healthy bees to produce and pollinate our top quality export dollars.

In additional to gut health, technology innovations in hive health are also starting to gain momentum. Canterbury start-up Hivemind, for example, has designed a remote hive monitoring system that enables beekeepers to remotely track and optimise hive productivity (honey production), hive health and increase security.

Hivemind in action

Designed by beekeepers for beekeepers, Hivemind’s flagship system involves scales that sit under a hive and a satellite or wireless hub – the “brains of the operation” – that measure the hive’s weight – a key indicator determining whether the nectar and honey flow is on. Every six hours the Hivemind system tells the scales to “wake up”, records individual hive data, sends it to a secure cloud database accessible to the subscribing beekeeper. According to founder, Christian Walsh, knowing the hive weight helps beekeepers choose the most optimal time to extract honey before the bees start cannibalising (eating) their own sweet goodness and whether they need to move hives to higher producing sites. The system’s security tracking module using GPS also lets beekeepers know if any rogues have stolen their hives or honey – and more importantly where to retrieve their stolen goods. An increasingly important add-on following the spate of NZ beehive thefts in recent years sparked by rocketing prices for mānuka honey.

Hivemind has also recently released a new tech module called “Hive Strength Monitor” that monitors the strength and health of hives using passive infrared sensors at the entry to the hive. The system tracks the number of bees coming and going, the time they fly in as well as brood temperature and humidity. The more bees going in an out, the stronger the colony. Stable brood temperatures and humidity also mean healthier broods. Walsh says access to this data helps beekeepers more accurately select strong hives for breeding which further increases their chances of generating higher honey crop yields. Beekeepers can also chose to insulate the hives in cooler months to reduce bee deaths.

Yet another superfluous tech gadget? Or a vital value-add for the apiculture industry? The latter it would seem.Walsh says those using the system have been able to increase bee-yard gains of around 4000 kg (honey) per year. Four years in, Hivemind already has over 60 customers in NZ and the business is steadily growing in popularity. It has also recently secured its first US Californian customer and is amidst crowd funding for a WIFI (vs its traditional satellite) version of the Hive Strength Module for hobbyist beekeepers in its quest to boost bee healthy and productivity. Similar companies exhibiting at Apiculture 2016 including Arnia, an innovative UK based hive health start up using acoustic hive monitoring technology, are yielding similar productivity results.

Extracting value from extraction

But sustainable and profitable beekeeping is not just about effective honey flow. It is also all about improving efficiencies of honey production after bees have worked their magic. Namely, at the extraction phase. Traditional methods for extracting and processing honey are painful and archaic to say the least. For decades beekeepers have had to safely cover, strap up and transport their many cumbersome hives to a commercial extraction facility. And then transport them all the way back again. With most hives almost invariably situated in remote and/or hard to get to locations, it’s a gruelingly inefficient process that places significant stress and pressure on bee colonies as well as putting them at risk of diseases and poor hygiene. As well as wasting a lot of valuable time for beekeepers. Thankfully, International Honey Products, a Canadian based operation, is starting to change all this with its novel mobile extraction technology that enables beekeepers to enjoy massive increases in honey yields, while spending more time doing what they do best – beekeeping.

The company has developed the world’s first commercial mobile extraction system that allows beekeepers to fully harvest, extract, process, filter, barrel and GPS tag around 1.4 tonnes of honey per hour right in their own bee yard.

International Honey Products’ mobile extraction system

While this might sound pretty normal, it’s not for the honey industry. “In every other farming industry we have state of the art columbines and tractors” says Collin Stone, company founder and president. “The way we milk cows and all the different farming processes, technology has hit every other industry. But in the beekeeping industry we’re still extracting the same way grandpa used to extract”.

“All of a sudden we were getting 15-20 percent higher yields in honey production” says Stone. Over time the company says beekeeper yields using the technology have soared up to of 46 percent. Huge gains by any standard. Why? The reduction of diseases, mites and pests primarily. Beekeepers no longer have to take hives and move them from location to location exposing them to less foreign diseases and bees are less stressed from transportation (both of which reduce honey production).

International Honey Products’ mobile extraction system

The onsite extraction technology has also resulted in a 42 percent increase in efficiencies. Namely, through the reduction of labour, vehicles, fuel, insurance, extraction equipment, hot rooms, maintenance, repairs, and utilities. “We went from fourteen employees down to four” Stone says. But reduction in extraction related employment are more than made up for through increased production volumes and profits. The the onsite mobile extraction technology allows beekeepers to run 36 percent more hives with the same amount of equipment and minor capital investment. Not only this, the company’s GPS tagging system means complete transparency of honey providence for discerning consumers worldwide.

For a seemingly simple innovation, onsite extraction technology is a massive win for the New Zealand industry. And is particularly good news for large scale commercial Kiwi honey producers like Comvita, Mossops and Waitemata Honey who are blessed with the ability to produce some of the most expensive and sought after honey in the world yet which is made in the most remote of settings. “We knew that with our system having been so good in North America, it would have similar benefits to New Zealand beekeepers”.

From Hive to Pot

It appears that NZ honey producers are also finally wising up to the benefits of technology even at the bottling and distribution stage of honey production. While RFID (radio frequency identification) technology is nothing new in industries like beef, sheep and even apparel (think Icebreaker’s world first BaaCode programme), it is for honey.

With the help of Callaghan Innovation, Hive Tech, a subsidiary of Honey Producer Barton Holdings, based in Taranaki, has developed its own RFID system that enables its 250g and 500g pots of premium Naki honey to be traced right back to the very hives they came from.

Hive Tech

Every one of the company’s hives are tagged with a Hive Tech RFID tag scanned in the field. Individual hive locations are plotted and recorded by GPS and then weighed and scanned against the extraction facility before honey processing. Data is then automatically uploaded into the cloud to produce a “Harvest Report” for landowners, beekeepers and extraction houses, which serves as proof of the amount of mānuka honey produced.

According to Barton Holdings owner, Brett Mascull, the system allows for total transparency and equitable profit share split for landowners. Under the system landowners can elect to receive a fee per hive, a hive fee/crop share payment, or a payment based solely on a share of the crop. “A bit like the share markets, it lets beekeepers and landowners establish their worth and instills a greater trust around using contract extraction houses”. In essence, each landowner knows he’s getting his slice of the increasingly valuable mānuka honey pie.

Hive Tech’s RFID tracking system also provides a valuable “hive to pot” story of provenance for consumers and proof of the honey’s authenticity. Customers can enter the traceability number on each pot of Naki Honey into the company’s website and trace and verify it right back to the source. While one might question whether the average punter would actually bother to trace the provenance of their honey right back to the hive, Mascull says it is a major differentiator that has enabled Naki Honey to command gob smacking premiums. Currently Naki’s 250gm 25+ mānuka blend is flying off the shelves at Queenstown International airport for a whopping $200 a pot and its exports to China and France are equally as lucrative. “In Asian markets they are really hot on this. They want to know what they’re eating and where its come from”.

With the technology having been met with great success for Naki honey, Hive Tech has not looking into how to package up and sell the tech to other players in the market.

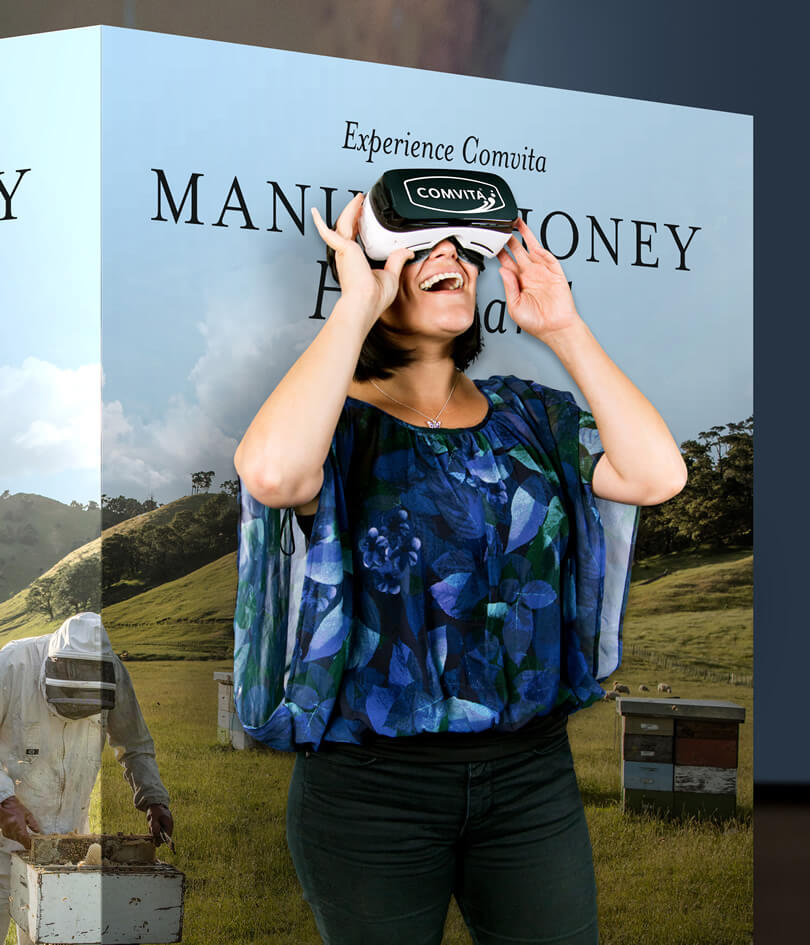

New Zealand-based Comvita, a global natural health products company, has taken the brand and technology experience around honey one step further with its unique virtual reality (VR) experience that enables customers to become completely immersed in Comvita’s ‘source story’. A key point of difference for the brand. Having tried it first hand at Apiculture 2016, I would have to agree.

Comvita’s virtual reality Source Story

Using a VR headset, viewers find themselves transported to New Zealand’s beautiful and remote Kaimanawa Ranges, where Comvita sources some of its highly sought-after Manuka honey. After that they land (via chopper nonetheless!) at one of Comvita’s most remote and stunning hive sites and watch as Comvita’s beekeepers harvest their unique product. The experience is available at its New Zealand retail stores (Auckland International Airport, the Viaduct and at Experience Comvita in Paengaroa) and the company is considering rolling it out across its international retail stores too. Comvita CEO, Scott Coulter, is pleased with the results of the company’s first foray into VR and sees it as a huge value-add to the business, “A key difference for our business is the purity of our product, the land it comes from and the lengths we go to ensure this is the case. So it makes sense for us to transport our customers to the source with VR. Because we really are New Zealand in a jar.”

The Flight Plath From Here

Yes, the apiculture industry is rife with old school beekeeping practices and traditionalism. And understandably so. Bees are a very special breed that command tender loving care, love and respect at every level. However, Apiculture 2016 shed light on a host on innovations, from pot to hive, that collectively hold great potential for New Zealand to extract even more value from our blessed and highly valuable apiculture sector. Across the entire value chain. All the industry needs is for some of our beekeeping industry old schoolers to loosen the reins of their traditional tried and true grandpa practices and appreciate just how the use of innovation and technology can enhance the health and wellbeing of their buzzing honey bees as much as their bottom-line. The direction we can take the industry has lofty heights. And if we let technology and innovation help us to chart the course the rewards will be sweet.

Leave a comment