Fifty million tonnes of computers, mobile phones and other electronics will be disposed of around the world this year, most of which will end up in landfill. Not only is this destructive to the environment, but it wastes valuable metals such as gold, copper and rare earths.

The metallic value of the 95,000 tonnes of e-waste generated by New Zealanders each year is worth over NZ $100 million. A recent UN Report highlighted that New Zealand collects no electronic waste (at least officially).

E-waste is a notoriously difficult feedstock to process, which is why the majority of it is landfilled but at Mint Innovation we saw an opportunity to develop a novel process to make e-waste become a source of value. We are initially focused on printed circuit boards (PCBs), which form the innards of modern electronics and contain much of the gold and copper content. A handful of specialised smelters in Europe and Asia are able to process these boards, but the associated processing charges and shipping costs mean that incentives for local e-waste collection are weak. Mint’s technology enables e-waste to be processed locally, thereby allowing cities and regions to recover value from what is currently a waste stream.

Mint’s journey began when, Matt Rowe and I, both self-proclaimed start-up veterans turned our minds to using microbial processes to concentrate value. We were looking for a process that could take low concentrations of a valuable metal, amongst a background of other metals, and concentrate it. We kicked many approaches around but none seemed to fit. A family trip to Arrow-town triggered an idea about soil microbes interacting with gold, and a subsequent feasibility study showed the concept held promise. This led to the creation of Mint, with the recovery of gold from e-waste being the first target.

Mint’s journey began when, Matt Rowe and I, both self-proclaimed start-up veterans turned our minds to using microbial processes to concentrate value. We were looking for a process that could take low concentrations of a valuable metal, amongst a background of other metals, and concentrate it. We kicked many approaches around but none seemed to fit. A family trip to Arrow-town triggered an idea about soil microbes interacting with gold, and a subsequent feasibility study showed the concept held promise. This led to the creation of Mint, with the recovery of gold from e-waste being the first target.

The current crop of specialised smelters for e-waste suffer from the scale at which they have to operate. Jason Herbert our Business Development Manager at Mint explains “The combination of high capital expenditure, costly downstream process systems and energy requirements force smelters to run at a fixed peak output to retain profitability. This means that hundreds of thousands of tonnes of e-waste needs to be sourced from aggregators all around the world”. Because of limited competition in this space, smelters only pay out a minority of the processed metallic value to their suppliers. This relationship disincentives the collection of e-waste, resulting in the disposal of e-waste into landfill – or worse yet, to the developing world where rudimentary and toxic recovery operations take place.

Unlike smelters, a Mint plant will be profitable at smaller scales. This is achieved through the deployment of its pioneering bio-metallurgical process, which is a hybrid of chemistry and microbiology. The microbes used are able to selectively absorb precious metals from a chemical soup created by dissolving the PCBs. This allows the valuable parts to be rapidly concentrated.

Unlike smelters, a Mint plant will be profitable at smaller scales. This is achieved through the deployment of its pioneering bio-metallurgical process, which is a hybrid of chemistry and microbiology. The microbes used are able to selectively absorb precious metals from a chemical soup created by dissolving the PCBs. This allows the valuable parts to be rapidly concentrated.

We have found that the current ways of dealing with e-waste in both New Zealand and the world are inadequate and the first iteration of Mint’s technology was crafted to address this problem. Due to its low capital requirements and operational expenses, our process cheaply concentrates metallic value, allowing more value to be returned to e-waste aggregators. This further incentivizes the collection of e-waste, diverting more of it away from landfill.

Our business development work has shown the local recovery of metals from e-waste represents a significant opportunity for New Zealand’s circular economy. The gold, copper and palladium targeted in Mint’s process all have strategic importance, with demand set to outstrip known global reserves of these ores. This makes the recovery of metals from end-of-life products increasingly important. Mint’s local recovery solution will help safeguard a jurisdiction’s metal supplies.

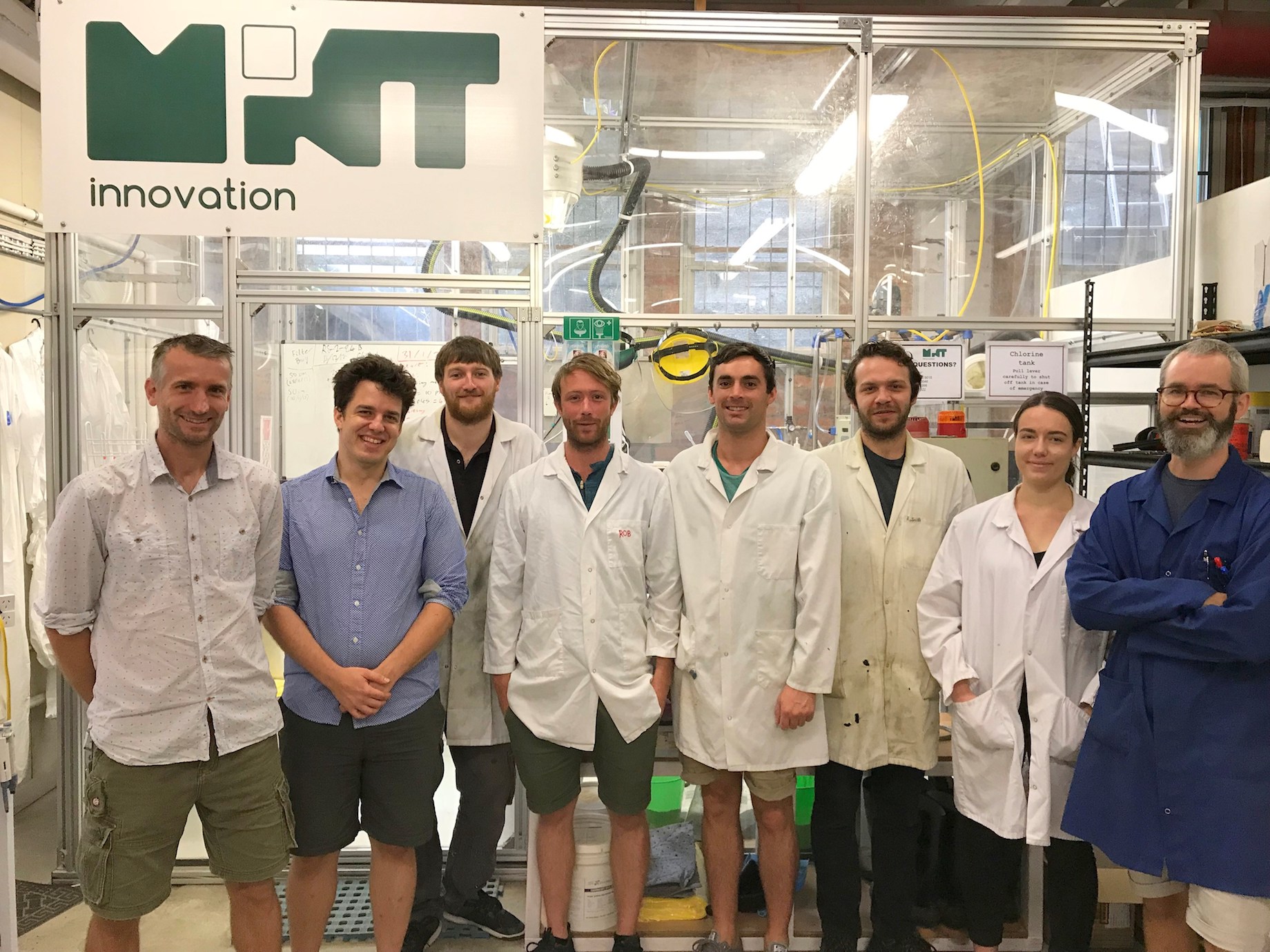

Our team at Mint has scaled its process from the lab bench to a pilot plant capable of processing kilograms of PCBs per run. Our next milestone is to build a demonstration facility in Auckland that’s capable of processing tonnes of PCBs and recovering kilos of precious metals. Senior Process Engineer Nick Moleta is behind the design of our demonstration facility that utilizes off-the-shelf components, creating a simple industrial process that has a similar footprint to a microbrewery. Keeping it simple allows Mint to develop a template that can be used throughout the world and be scaled to match the needs of different regions.

Our team at Mint has scaled its process from the lab bench to a pilot plant capable of processing kilograms of PCBs per run. Our next milestone is to build a demonstration facility in Auckland that’s capable of processing tonnes of PCBs and recovering kilos of precious metals. Senior Process Engineer Nick Moleta is behind the design of our demonstration facility that utilizes off-the-shelf components, creating a simple industrial process that has a similar footprint to a microbrewery. Keeping it simple allows Mint to develop a template that can be used throughout the world and be scaled to match the needs of different regions.

Following the success of a demonstration plant, we plan to construct a commercial facility that can address the e-waste produced by a large city. For example, a Mint plant in the state of Victoria, Australia, could be scaled to process 2,000 tonnes of PCBs per year while recovering 400 kilos of gold and 400 tonnes of copper. From there Mint plants will be rolled out to the world, helping establish New Zealand as a leader in building the circular economy.

Leave a comment