Lubricants are an essential part of any piece of moving or rotating machinery. The applications in which lubricants are used are countless, ranging from speciality industrial compounds used in power plants to basic penetrating oils used on squeaky door hinges.

Typically, lubricants are based on petroleum fractions (aka mineral oils), liquid by-products of crude oil refining. Mineral oils have been used in the production of lubricants for many decades. Sufficient technical parameters, large extractable volume and relatively low value of mineral oils have historically been the driving forces.

However, mineral oils are known to be harmful to human health and the ecosystem. These impacts are highly important since approximately 50% of all lubricants used worldwide inevitably end up in the environment. This happens through total loss lubrication, accidental release or spills and ultimately results in billions of litres of toxic oil spread around forests, fields and waterways – and nearly always without anyone noticing! The growing concern about environmental damage caused by intentionally discarded or unwanted petroleum based lubricants is very real.

“Millions of litres of mineral oil pollute the New Zealand environment each year and one litre of mineral oil can contaminate up to a million litres of our drinking water.”

Here in New Zealand, it is estimated 30 million litres of mineral oil based lubricants lost into our pristine environment every year. Industries with the highest concerns of negative environmental impact include forestry, marine, agriculture, earth moving, mining and construction, among others. With only one litre of mineral oil capable of contaminating up to 1 million litres of drinking water, it is easy to see that losses of lubricating oil are an unrecognised problem in New Zealand’s environment.

PF Olsen, the leading forestry management company is encouraging its contractors to use biodegradable chain bar lubricants in harvester & processing heads and chainsaws.

Some good news comes thanks to modern research and technology. Suitable, cost-competitive, environmentally responsible alternatives have been developed to easily replace the mineral oil based lubricants and mitigate their negative environmental effects. This is particularly important for operations of equipment and machinery in environmentally sensitive areas or with a high-risk rate of a lubricant discharge.

These environmentally friendly biodegradable lubricants, simply called bio-lubricants, are manufactured using vegetable and synthetic ester base oils. The main property required of any bio-lubricant should be its ability to be easily broken down within a reasonable time by microorganisms in the soil and water, and have minimal impact on the ecosystems. At the same time, stringent performance standards must be met or exceed against the traditional mineral oils.

Characteristic features of biodegradable lubricants:

- rapidly degrade in natural environment – biodegradability levels can reach well over 90% within the first month, whereas mineral oil is poorly biodegradable (typically around 20 % and can lead to a contamination of groundwater for up to 100 years)

- are non-toxic and produced from renewable materials – to ease up on the overuse of fossil fuels. Base oils used are vegetable and synthetic esters, which are 100% renewable bio-products.

- have a positive impact on reduction of CO2 emissions

- are purposely designed to increase performance, efficiency and reliability.

Strong R&D is behind development and quality control of LUBECO bio-lubricants.

Europe and North America have the most developed markets for bio-lubricants. They have strict regulations, mandatory purchase requirements and a strong degree of self-regulation through business leadership and trade associations. Implementation of comprehensive eco-labelling programmes also contributed to a fast recognition and acceptance of bio-lubricants.

The EU Ecolabel is the primary pan-European green label used to define bio-lubricants across Europe, and by extension, become a reference point for customers in Asia, America and the rest of the world. The two specific aims of the EU Ecolabel are to limit harm caused to the water and soil environment though product’s use, and reduction of CO2 emissions to the atmosphere.

Whereas the US EPA 2013 Vessel General Permit (VGP) introduced by the US Environmental Protection Agency is the most significant regulation specific to the marine industry. According to the US EPA 2013 VGP vessels are required to use environmentally acceptable lubricants in all oil-to-sea interfaces.

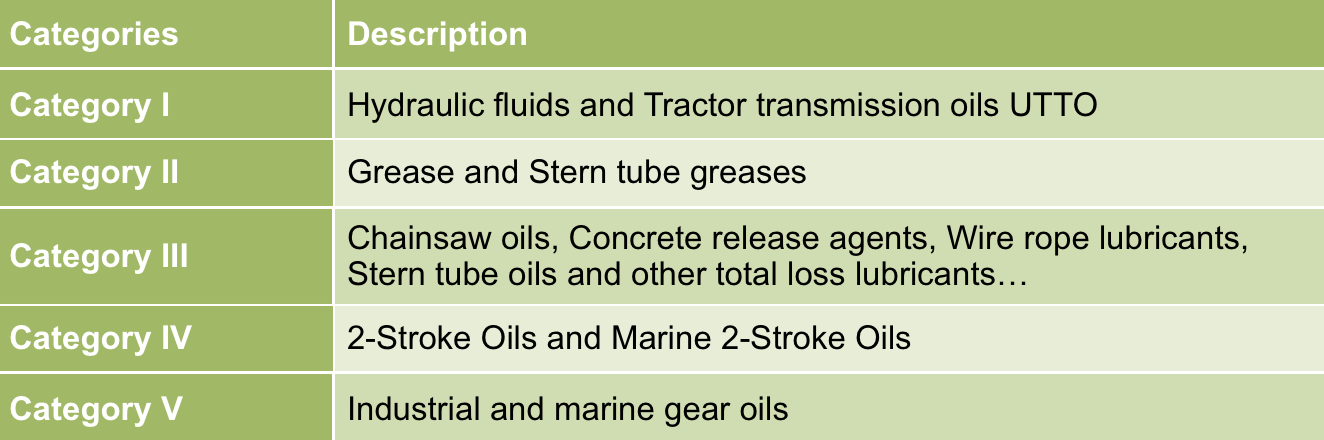

The EU Ecolabel recognises 5 product categories with different requirements

A growing number of countries are successfully following the trend and implementing effective programmes and policies to promote bio-based products, bio-lubricants included.

New Zealand has seen positive signs in recent years when it comes to replacing mineral oil based lubricants with bio-lubricants. A number of companies and industry bodies have recognised growing concern of environmental damage and adopted lean and green initiatives. This growing sense of environmental responsibility positively affects all dimensions of operations. However, there is a general feel that much more needs to be done. A strong leadership and government direction are essential to promote sustainable products and overcome existing inertia in the market.

SANTY MARIA, a state-of-the-art fishing vessel by MOANA New Zealand and RMD MARINE working with environmentally friendly hydraulic fluids and other LUBECO high-performance bio-lubricants.

Driving the change to bio-based lubricants

For LUBECO bio-lubricants our kiwi story goes a good decade back. Mr Ladislav Zelenka Snr, the chairman of our mother company BIONA Group – a leading European manufacturer of bio-lubricants – came to New Zealand for a holiday and was amazed by this beautiful country and sound economy. But he could not equate our great environmental credentials with virtually zero requirements for use of bio-based lubricants. This particularly applied where there was a high risk of polluting the pristine natural environment.

This discovery led to an intensive planning to expand the availability of quality bio-lubricants manufactured to EU Ecolabel standards here in New Zealand, in order to help the local industry develop a more sustainable practice with a strong focus on environmental protection. The plan became reality in early 2014 when a local office was opened in Auckland. It provides direct support to customers and the growing local distribution network, as well as continuous education about bio-lubricants in general. A long term vision has also been set to establish a local manufacturing facility to help better service New Zealand’s progressive industries.

Being close to our customers and distributors with a real-time technical advice is critical. Like any technology-switch, people need to be educated about the new products, why they work better and why they are environmentally much friendlier compared to the normally used mineral oil lubricants.

When it comes to manufacturing of bio-lubricants there is indeed a lot to talk about. Sourcing and processing of vegetable base oils at BIONA Group provides a good insight into the sustainability of the entire production cycle. A rapeseed grown by a contracted group of strategically located farmers is purchased for processing. It is cold-pressed to extract virgin rapeseed oil of the highest quality, which later is treated and used as base oil for bio-lubricants. The by-product of the initial extraction of rapeseed oil is called rapeseed meal, or rapeseed cake. This protein-rich ingredient is a prime feed for all classes of livestock; hence it is sold back to the farmers and the cycle continues.

Cold-pressing of rapeseed at our processing plant.

As the only specialised manufacturer with a direct presence in New Zealand we are committed to making a difference in the local community. We can already see a positive shift towards green technology as people and companies become more responsible and look for sustainable solutions.

While several industry innovation leaders from forestry, construction, marine and agriculture sectors have already recognised the added value of using bio-lubricants to their businesses, there is an emerging need for involvement of other big players as well as recognition and endorsement of bio-lubricants at the government level.

At present our lubricants are imported from Europe using 100% renewable materials. New Zealand has a good availability of the raw materials, particularly rapeseed for manufacture of vegetable ester-based products. We’re optimistic that there is the potential for production to occur here in the near future, dependent on market growth. Policy endorsements and leadership by large companies are going to be significant elements in promoting the use of bio-lubricants. The opening for a proven green technology is a simple way to immediately help protect our environment and promote the clean green New Zealand we all benefit from.

Leave a comment